|

|

Problem |

Solution |

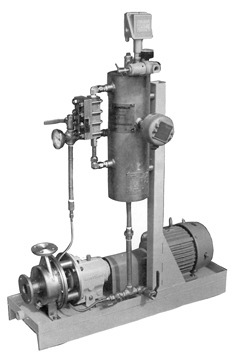

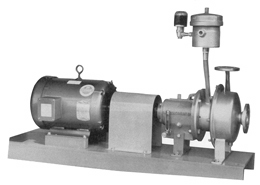

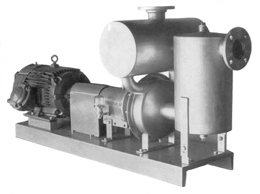

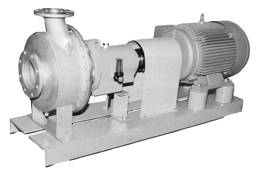

| Provide commercial horizontal pedestal mounted pumps (8) for erosive/abrasive slurry/sludge transfer service Water, radioactive with Uranium and other constituents in suspension, up to 10% solids by weight, up to 1/4" size with Brinell hardness of 370, 1.067 SG, ambient temperature Duty: 65-70 GPM @ 686-791 feet total head at 51-59 Hertz operation with max impeller (14.50" diameter) |

|

Model: 6000 FHB-HD2 (A10-2B) ANSI-type pedestal mount, abrasive-resistant, extra heavy-duty, double-sealed design Suction: 2" FF Flange (300#) Discharge: 1-1/2" FF Flange (300# rating) on centerline at 9 o'clock position |

|

Features |

|

|

|

|

Problem

|

Solution

|

|

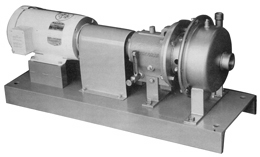

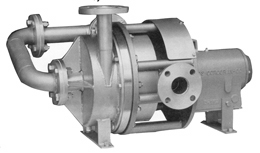

Recirculating pump for "heavy water" (0.89 SG & 73 Cp viscosity), designed for 250°C (482°F) and 700 PSI inlet pressure: 8 GPM @ 40 FT TH (19.5 PSI boost). |

|

|

Model:

2000F-HD3 (AA05-2)

Material: 316 Stainless Steel Size: 3/4" x 1/2" RF FL (600#) |

|

|

Features

|

|

|

|

|

Problem

|

Solution

|

|

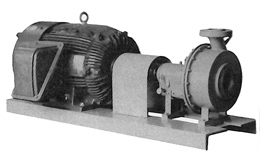

Nuclear Facility clean-up site required dilute caustic (3 to 5%) circulating pumps (located outdoors) designed for direct water wash-down, zero emissions and continuous duty: 12 GPM @ 140 FT TH (low flow, high head) |

|

|

Model:

3000FH (AA05-1)

Pedestal Mounted (Group I) Double-Sealed Material: 316 Stainless Steel Size: 1 1/2" x (1/2) FF FL (150#) |

|

|

Features

|

|

|

|

|

Problem

|

Solution

|

|

Scrubber recycle pumps for municipal sludge management facility, rate 100 GPM at 75 FT TH, required zero emmision and full independence. |

|

|

Model:

3000FH (AB-1)

Pedestal Mounted, Double Sealed Centrifugal Size: 3 x 1 1/2 FF FL - 4.75" |

|

|

Features

|

|

|

|

|

Problem

|

Solution

|

|

Chemical plant constructor required "Heavy-Duty Pedestal Mount Hydrocarbon Liquid Centrifugal Pump" for liquified natural gas facility: 326 PSI inlet pressure (duty: 96 GPM @ 15 PSI boost @ 0.54 SG). |

|

|

Model:

3000F-HD3 (A10-2)

Heavy-Duty Pedestal Mount (Group II) Size: 2 x 2 RF FL (300#) |

|

|

Features

|

|

|

|

|

Problem

|

Solution

|

|

(Low flow, high head) |

|

|

Model:

4000F (AA05-1)

Material: 316 Stainless Steel Size: 1 1/2" FNPT x 1/2 FNPT (Tangential Discharge) |

|

|

Features

|

|

|

|

|

Problem

|

Solution

|

|

Remote location pumping caustic (50% NaOH at ambient temperature) with no provision for external water flush; 30 GPM @ 166 FT TH |

|

|

Model: 4000FQ

(AA05-1) |

|

|

Features

|

|

|

|

|

Problem

|

Solution

|

| Pump

a proprietary water-like substance in a reverse osmosis system at 1000

PSI inlet pressure. |

|

|

Model:

4000 F-HD

Pedestal Mount, End Suction, Heavy-Duty Centrifugal Material: 316L Stainless Steel Size: 1.5" x 1 FNPT |

|

|

Features

|

|

|

|

|

|

|

|

Problem

|

Solution

|

| At

298 PSI inlet pressure, produce 80 PSI boost at 36 GPM of 100°C CBS

carbamate solution. |

|

|

Model:

4000 F-HD3 (AA-2)

|

|

|

Features

|

|

|

|

|

Problem

|

Solution

|

|

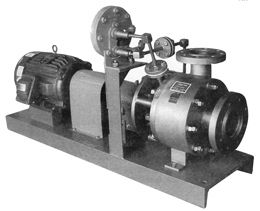

Chemical manufacturer must batch circulate an abrasive slurry (water with 10% barium hydroxide and 2% titanium dioxide), 392° F, 250 PSI inlet pressure, 1.1SG, pH 14: 200-300 GPM @ 20 PSIG boost |

|

|

Model:

4000 F-HD3 (A70-2B)

Size: 4 x 3 RF FL (300# rating) Motor: 10 HP, 1760 RPM, explosion-proof, 215T |

|

|

Features

|

|

|

|

|

Problem

|

Solution

|

|

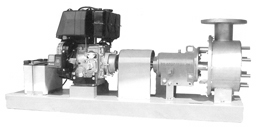

International Precious Metals Mining Corp. required a diesel engine driven pump to move a corrosive nickel/copper solution through a pipeline in the remote Canadian wild at 275 GPM @ 25 ft. TH |

|

|

Model:

5000F (A80-2)

ANSI Pedestal Mounted Centrifugal Size: 6" FF FL (150#) x 6" (4) FF FL (150#) |

|

|

Features

|

|

|

|

|

Problem

|

Solution

|

| Paper and specialty forest products manufacturer required 90 GPM @ 90 FT TH of slurry (Na 2SO 4, H 2SO 4, NaClO 3, ClO 2, H 2O2) with 10% gas at 190°F. |

|

|

Model:

5000FH-VOR (A50-2B)

ANSI Pedestal Mount Double-Sealed Recessed (Vortex) Impeller Size: 3 x 1.5 FF FL (150#) |

|

|

Features

|

|

|

|

|

Problem

|

Solution

|

|

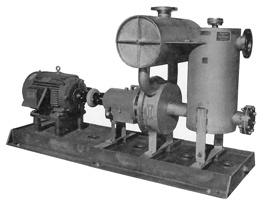

Self-prime JP-4 fuel at rate of 300 GPM at 81 FT total head. |

|

|

Model:

5000 F-SP

Pedestal Mounted Self-Primer Size: 3 x 3 FF FL |

|

|

Features

|

|

|

|

|

Problem

|

Solution

|

|

Major Artificial Sweetener Manufacturer required 126 GPM at 1000 FT TH (446 PSIG at 1.03 SG) of water with 2% HCI, 3% NaCl and 2% Organics |

|

|

Model:

5000 FM2

Pedestal Mounted, Rear Suction, Two Stage (opposed impellers) Centrifugal Suction: 2" FF FL (150#) Discharge: 1 1/2" RF FL (300#) |

|

|

Features

|

|

|

|

|

Problem

|

Solution

|

|

(Low Flow, High Head) |

|

|

Model:

5000 FM-2

Material: 316 Stainless Steel Size: 2x1 RF FL (300#) |

|

|

Features

|

|

|

|

|

Problem

|

Solution

|

|

Pump various mixtures of chromic acid and sulfuric acid at high temperatures - up to 160°F. |

|

|

Model:

A80-2

Material: Fabricated of commercially pure Titanium Size: 6' x 4' x 13 |

|

|

Features

|

|

|

|

|

Problem

|

Solution

|

|

Paper plant required a pump with an outdoor location for 34 GPM @ 185 Ft TH, 93% H2SO4 (1.83 SG), at 1750 RPM. |

|

|

Model:

6000F (AA05-2)

Material: All Carpenter 20 Cb-3 Size: 2 x 1/2 FL |

|

|

Features

|

|

|

|

|

Problem

|

Solution

|

|

Major midwest steel producer required corrosion-resistant pumps (4) for "strong ammonia liquor" application (NH 3, H 2S, HCN) with smooth, vibration-free operation under low flow, high head conditions: 20 GPM @ 139 FT TH and 35 GPM @ 128 FT TH. |

|

|

Model:

6000F (A10-2)

Pedestal Mount Material: Commercially pure Titanium, ASTM Grade 2 (shaft: ASTM Gr. 4) (including all pump fasteners) Size: (Pump) 2x1 internal, built to conform to ANSI A20-2, 3 x 1.5-13 external dimensions and connections |

|

|

Features

|

|

|

|

|

Problem

|

Solution

|

|

Boiler feed water

application: |

|

|

Model:

6000F (A40-2B)

Heavy Duty Ansi-Type Centrifugal Size: 4" RF FL (150#) x 3" RF FL (600#) |

|

|

Features

|

|

|

|

|

Problem

|

Solution

|

|

Major paper products manufacturer required abrasion-resistant pump for erosive, dense (1.5SG) lime slurry application: 200 GPM @ 140 FT TH |

|

|

Model:

6000F (A40-3)

Pedestal Mount Centrifugal Material: Malcomized Stainless Steel (.005 - .007 case depth & 93-94 Rockwell 15N hardness) Size: 4 x 3 FF FL |

|

|

Features

|

|

|

|

|

|

|

|

Problem

|

Solution

|

| Department of Energy Application: Deionized water at 450°F, 1250 PSI inlet pressure, requires 65 GPM @ 141 FT TH (50 PSI boost at 0.82 SG). |

|

|

Model:

6000 F-HD3 (A10-2B)

Material: 316 Stainless Steel Size: 2 (900#) RF FL x 1 (1500#) RF FL |

|

|

Features

|

|

|

|

|

Problem

|

Solution

|

|

Engine valve manufacturing company required 800 GPM @ 200 FT TH of deionized water at ambient temperature. |

|

|

Model:

8000F (A80-3)

ANSI-Type, Pedestal Mount Size: 6 x 4 FF FL (150#) -17 |

|

|

Features

|

|

|

|

|

Problem

|

Solution

|

|

Major Oil Company required two self-priming pumps subject to their extremely strict QC & QA standards: Duty: 400 GPM @ 210 FT TH (including up to 20 FT lift) of waste water with dilute H2SO4, NaOH & MEK and NPSH-A of 15 FT |

|

|

Model:

8000F-SP (A40-3)

Size: 4x4 RF FL (150#) -17 |

|

|

Features

|

|

|

|

|

Problem

|

Solution

|

|

Bahamian entrepreneur

required a centrifugal self-primer to lift (approx. 8') limey sea water

from indigenous coral wash-down operation (800 GPM @ 189' TH) |

|

|

Model: 8000F-SP

(A80-3) |

|

|

Features

|

|

|

|

Problem |

Solution |

Monosodium titanate slurry in caustic solution with ‹5% solids, ‹50 Microns in size, 120°F, 1.26 SG, 1300GPM @ 74ft. TH: for Dept. of Energy "Saltwater processing facility cross flow filter full scale test" for radioactive high level waste |

|

Model: 6000 FH-HD1-VOR (A90-3) |

|

Features |

|

|

|